Modules Are Fully Integrated Into the DW Layout Editor and Can Be Added As Needed To Support Your Evolving Design Workflow

The following modules seamlessly integrate into the DW Layout Editor and are fully accessible via GPE, add them as needed to customize and scale your workflow to match your design goals.

Verification modules

- Design Rule Check (DRC)

- Advanced Design Rule Check (XDRC)

- HLVS: Extraction & Layout vs. Schematic (LVS)

Data Conversion

- AutoCAD Conversion & GDSII Validation

- Data Conversion for Manufacturing (DCM)

- Custom Conversion Services

Productivity modules

Miscellaneous

Ready to take your processes to the next step ?

Speak with our team to discover tailored solutions for your business.

We can support you through live virtual sessions tailored to your team’s needs.

Design verification is a critical step in the back-end design process. Ensuring manufacturability before production is key to maximizing yield, which is why compromising on quality isn’t an option. You need a DRC capable of handling the complex rules required by modern foundry processes.

Beyond manufacturability, verification modules also confirm that devices are built to your specific design intent. They validate device inventory, specifications, and interconnects against the reference netlist to ensure everything is properly documented and connected as designed.

Design Workshop Technologies provides a complete suite of verification tools, including DRC, XDRC, and HLVS, to support all these requirements.

Design Rule Check (DRC)

Integrated, Flexible, and Precise Layout Verification

The DW Layout Editor’s Design Rule Check (DRC) offers a powerful, integrated solution for validating physical layouts quickly and accurately. Supporting both single-layer and two-layer rule checks—including width, spacing, inclusion, and overlap—our DRC uses a robust Boolean engine to handle complex all-angle logic combinations.

Customize verification and exception areas effortlessly, and run checks interactively through an intuitive graphical interface or automate them using GPE scripting.

Errors are clearly highlighted with color-coded markers and detailed labels, making it easy to pinpoint issues. Plus, comprehensive graphical error reports can be shared seamlessly with colleagues, vendors, or clients using our Viewer software products, enhancing collaboration and speeding up design reviews.

Advanced Design Rule Check (XDRC)

Unmatched Accuracy and Flexibility for Cutting-Edge Technologies

The XDRC module delivers an industry-leading physical verification tool tailored for the most advanced technology nodes. With unparalleled performance and precision, XDRC excels at handling all-angle geometries, detecting layout errors that other tools may miss.

XDRC can cover the rule sets of all the major foundries, XDRC’s powerful yet easy-to-learn scripting language offers comprehensive commands for every verification need, including width, spacing, overlap, extensions, conditional checks, property evaluations, error filtering, and connectivity rules like antenna checks.

Ideal for electronics, photonics, MEMS, and hybrid designs, XDRC provides a cost-effective and reliable solution for interactive physical verification, helping designers confidently prepare layouts for tape-out and manufacturing.

Design Rule Verification (XDRC)

HLVS: Extraction & Layout vs. Schematic (LVS)

Accurate Network Extraction and Validation for Any Technology

The HLVS module unlocks powerful features like electrical layout extraction and netlist comparison, critical steps in ensuring design accuracy. Fully integrated with the DW Layout Editor and its flexible GPE scripting environment, HLVS can be easily customized to support virtually any process technology or design application.

HLVS includes:

- HLE (Hierarchical Layout Extraction): Automatically generates a netlist from your physical layout, capturing both generic and hierarchical devices along with parameters and parasitics.

- LVS (Layout vs. Schematic): Compares the extracted netlist against a reference to quickly identify mismatches or connectivity issues.

With HLVS, designers gain a robust, efficient toolset for verifying that the physical implementation faithfully reflects the intended schematic, ensuring design integrity from layout to fabrication.

AutoCAD Conversion & GDSII Validation

From General CAD to Fabrication-Ready Layouts

While AutoCAD is a popular format for mechanical design, simulation, and general CAD applications, it’s not ideally suited for mask manufacturing.

Design Workshop Technologies bridges this gap with a Bidirectional AutoCAD Translator that includes built-in GDSII compliance validation. This powerful tool enables designers to seamlessly convert AutoCAD files into manufacturing-ready mask layouts within the DW Layout Editor—ensuring accuracy, efficiency, and compatibility with industry standards.

Data Conversion for Manufacturing (DCM)

Support for GDSII, OASIS, and Advanced EBEAM Formats

The DW Layout Editor comes standard with support for GDSII and OASIS file formats. For advanced manufacturing workflows, the optional DCM module adds compatibility with key EBEAM formats including MEBES, JEOL-01, JEOL-51, and Cambridge SPD.

Fast, reliable data conversion is essential for any CAD system that integrates with multiple tools across the design and fabrication pipeline. The DW Layout Editor ensures smooth interoperability with a wide range of industry-standard formats.

Custom Conversion Services

Need a converter that’s not listed? Contact us to check availability or request support for additional file formats.

PCell Developer Kit

Accelerate Layout Creation with Parametric Cells (PCells)

Design Faster. Customize Instantly. Iterate with Ease.

Save valuable time by automatically generating layout cells with DW Layout Editor’s powerful PCell technology. Whether you’re using built-in library components or defining your own, PCells let you quickly create complex designs through simple parameter inputs.

Just enter your values, via the intuitive interface or a script, and the device layout is generated instantly. Need to make a change? Select the cell, update the parameters in the dialog box, and the layout is redrawn on the spot.

At the core of this flexibility is DW Layout Editor’s GPE scripting engine, which gives you complete control over how PCells are defined and behave. It even detects changes to PCell definitions and ensures all instances are automatically updated.

With PCells and the DW Layout Editor, you get the ideal balance of speed, precision, and customization, making every design faster to build and easier to refine.

Die Serialization

Easily Track and Identify Every Chip with Automated Wafer Serialization

Our Wafer Serialization module streamlines the process of adding unique, printable labels to each chip on your layout—ensuring precise row-column identification across the wafer. With full integration into the user interface and GPE support for seamless automation, it fits effortlessly into your workflow.

Packed with flexible options, you can customize numbering direction, orientation, fonts, and more, giving you complete control over how your chips are marked. Simplify traceability and boost manufacturing efficiency with a serialization solution built for modern design needs.

Photonics Element Library

Streamline Your Path from Design to Fabrication

The Photonics Element Library delivers a complete backend solution for photonic device design. Built specifically for the photonics industry, it takes full advantage of the DW Layout Editor’s powerful features, including all-angle geometry, native GDSII support, and a hierarchical design database.

With a rich collection of parametric optical elements and ready-to-use waveguide components, the library enables fast, accurate transitions from simulation to fabrication-ready layouts, helping you save time, reduce errors, and bring products to market faster.

Document Photonics Element Library (PEL)

Parametric Waveguide Elements for Seamless Photonic Design

Each waveguide element is a parametric cell (PCell) developed by our engineers to meet both photonic design standards and fabrication requirements. Designers can easily use these elements by selecting the desired component, assigning parameter values, and placing it into the layout. This process can also be automated using the GPE. Once placed, the waveguide element is immediately available for viewing or editing in its ready-for-manufacturing form.

Element list

- Linear

- Arc Bend

- Arc S-Bend

- Sine S-Bend

- Cosine S-Bend

- Polynomial

- Elliptic

- Ring

- Polygon

- Linear Taper

- Arc Taper

- Arc S-Bend Taper

- Sine S-Bend Taper

- Cosine S-Bend Taper

- Polynomial S-Bend Taper

- Exponential Taper

- Parabolic Taper

- Circular Lens

- Elliptic Lens

- Parabolic Lens

- Hyperbolic Lens

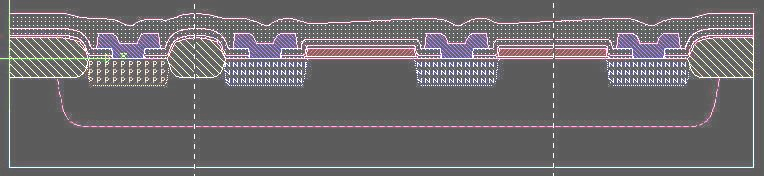

Cross-Section Viewer

Generate Accurate Cross-Section Views for Design Documentation

This module allows you to create precise cross-section views of your design using a GPE script. Each process step like Implant, Diffuse, Grow, Deposit, Etch, and Planarize, is scripted to build the view step by step. Parameters such as thickness, width, depth, slope, and oversize enhance control and accuracy. High-quality visualizations depend on precise input and a strong understanding of process mechanics to ensure realistic and effective results.

Testimonials

Satisfied and loyal users are what keeps a company successful

As a CAD “power user”, I find DW to be a great program to use, that I can work with quickly and efficiently. The flow of work for the user is quite well designed, and the user interface is optimized for the user. I think what sets DWT aside from most competitors is the extremely powerful programming language, which provides immense extendibility and customization of the entire program.

Richard J.Bojko – Senior Engineer, Seagate Technology

We would like to thank Design Workshop Technologies for supporting Lightwave Microsystems in our goal to be the world-leading manufacturer of integrated optical components. For over four years, Lightwave Microsystems has been using DW as our mask layout software of choice to build our integrated optical components. DWT has been supportive by responding to our specific needs and requirements. DWT has an excellent technical support team that is responsive and knowledgeable. We look forward to building a great business relationship in the future.

Calvin Ho – CAD Engineering Manager, Lumentum

Cree Inc. utilizes DW as our preferred CAD tool for the implementation of, primarily, next generation microwave FET and microwave MMIC amplifier designs in SiC (Silicon Carbide), and GaN (Gallium Nitride). Refer to Cree’s website at www.cree.com for more information regarding specifications, target applications, partnerships, and customers. We have also employed DW in power device design including SiC power mosfets and schottky diodes. The power of the DW boolean tools has enabled designs that would have been previously too labor intensive to have been cost/time effective to pursue.

Dan Fritz – Test Engineer, Cree Inc.

I particularly appreciate the versatility of DW that we use to design photomasks for diffractive optics as well as for MEMS-like devices such as microbolometers, lightvalves or micromirrors. DW prevents any positioning error of MEMS on the CMOS circuitry because the design is made directly on top of the CMOS library. I also want to mention the GPE programming capabilities of DW for automatic generation of very complex structures that would be otherwise very difficult to build.

Christine Alain, M. Eng. – Program Manager, Microfabrication, INO

Here at Ultratech Stepper, Inc. we decided back in 1991 that it was time to purchase mask layout software to bring this capability in-house, rather than depend upon outside sources. After our investigation into the various options, we chose Design Workshop Technologies’ DW and have been using it for the past 12 years. We started with the Apple platform, and now have licenses for both the Apple and the PC platforms. We have completed cad layout for hundreds of Ultratech Stepper reticle designs for the steppers we produce, and have also found DW very useful for the verification of device layouts of our Customers. The ease of use of the Layout Editor of DW has always been a big plus.

Alan Walther – Senior Reticle Engineer, VEECO

At RSC, we’re an independent privately owned company focused on creating innovative technologies and delivering the winning technical edge in partnership with our customers. With intense time-to-market pressures our designers need proven layout software that works reliably and DW fills this need. DW is an impressive layout tool. Two outstanding features of DW are the native GDS database that guarantees seamless conversion and export of layout data to the GDS format, and the graphical programming environment (GPE) that gives access to all the capabilities of DW for automating advanced layout tasks.

Jonathan B. Hacker – Manager RF Circuits and Applications, Teledyne, Scientific and Imaging LLC